Quality

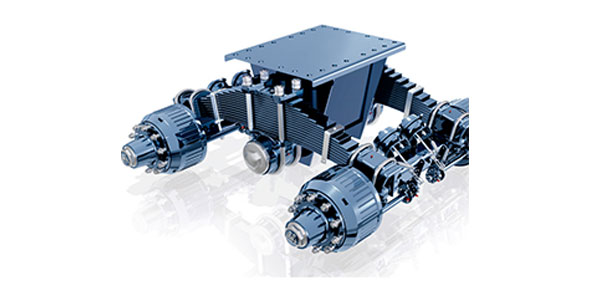

Every day, thousands of trucks on the world's roads travel to ensure we are supplied with what we need. However, this logistical masterpiece should not be taken for granted as everything needs to dovetail. It is, after all, the running gear that is exposed to huge loads mile after mile, travelling on rough surfaces, in cold weather, high temperatures and dust.

Economy

At the same time, it is not just important to transport the cargo safely, but also economically. BPW offers you the complete trailer running gear from a single source: from the axle and the bearing to the suspension, brake and telematics. Our telematics applications ensure greater economy, as efficient fleet management reduces operating costs.

Perfection

Everything is perfectly attuned within a system that can cope with the most exacting requirements. This also includes outstanding ease of maintenance, such as a brake service conducted in record time. This represents an effective way for you to save on downtime, expenditure and costs, meaning that you can continue driving more economically with BPW.

Commercial Vehicles

Brakes

Drum brake and cost reducer in one unit

Drum brake and cost reducer in one unit

Drum brake and cost reducer in one unit

With more than 11 million units sold worldwide, the BPW drum brake is now the embodiment of a reliable brake for towed vehicles. It sets new standards for lifecycle costs thanks to its robust construction and ease of servicing. Our designers have succeeded in optimising the classic drum brake further, resulting in the ECO Drum. The result: A considerable weight reduction, improved sealing and lower wear.

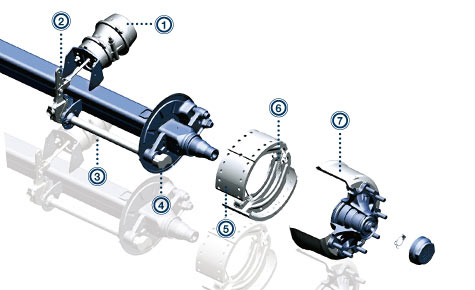

Function:

The force of the brake cylinder below (1) acts via the slack adjuster (2) and causes the brake camshaft (3) to rotate. The S-cam (4) forces the brake shoes (5) apart, pressing them against the inside of the brake drum (7). When the brake is released, the brake camshaft (3) rotates the S-cam (4) back to its neutral position. The brake shoes (5) are returned to their initial position by tension springs (6).

ECO Drum - Features and Benefits

- Universally applicable

- Enclosed construction enables use under the harshest conditions

- Quick and easy brake service thanks to the patented ECO principle (European patent 0 407 719 B1)

- Low operating and spare part costs

- Weight reduction of about 18 kg for ECO Plus 2 (9 t with air suspension)

- More straightforward installation by improved dust cover attachment

- No dirt ingress thanks to revised sealing system

- Simple to check drum and pad wear using the redesigned observation holes

- Reduced wear for lower lifecycle costs

- Can be approved without restrictions for electronic trailer brake systems (EBS)

- Large amount of abradable material

- Cataphoretic dip-coating with zinc-phosphating (KTLZn) for the best possible surface protection

WEAR and DAMAGE Characteristics on Friction Brakes

DRUM Brake - click on image to download

Economy is its life

Economy is its life

Economy is its life

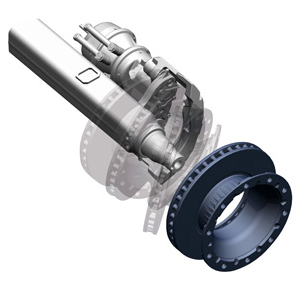

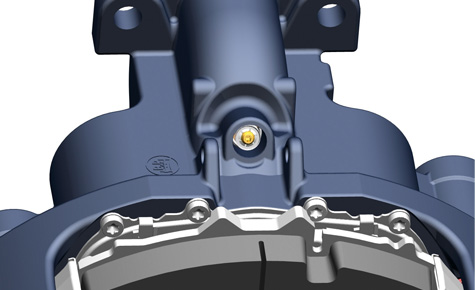

BPW's ECO Disc is the disc brake which has really earned its renowned name. From the very start, BPW engineers have ensured all the running gear components are perfectly coordinated and without any trade-offs. The ECO Disc thus offers you a whole range of benefits which pay off for you in terms of more loading possibilities, quicker brake service and a high-quality and long life disc brake.

Up to 39 kg lighter thanks to Compact Design

ECO Disc makes each axle up to 13 kg lighter. In a three-axle unit, this adds up to 39 kg. It is an enormous weight saving that has only been made possible with innovative BPW Compact Design. After all, BPW has succeeded in connecting the brake directly to the axle beam and integrating it fully into the system.

The advantages are obvious: fewer interfaces and much lower weight. And all this with the same level of stability. How do you benefit? Greater efficiency with a higher payload. ECO Disc - the best demonstration that, quite simply proves - less is more.

BEFORE:

AFTER: With Compact Design, for the first time the brake is directly connected to the axle beam.

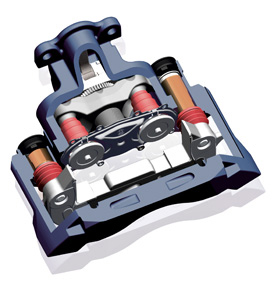

Extremely straightforward maintenance thanks to our attention for details

The innovative Compact Design of the ECO Disc not only reduces the axle weight, it is also no longer necessary to remove the brake calliper during a disc change. It is a clever solution which, in conjunction with the tried and tested ECO principle, saves you valuable time. The ECO principle makes it possible to install the hub bearing unit using the Formula 1 method. With the ease of access to the retaining spring, it is possible to renew the pads and disc in record time. In short: ECO Disc reduces downtime, service costs and the installation complexity of normal brake services.

Thanks to the ECO principle: quick and easy brake disc change without removing the bake calliper - see below:

Extremely robust thanks to interior seals

We have exposed the ECO Disc to the most extreme conditions in worldwide field trials. The trailer disc brake merely shrugged off icy weather in the Arctic Circle as well as the dust and red hot heat of the Australian outback. This is due in part to the innovative interior BPW seals. They are more effectively protected against thermal and mechanical damage, thereby preventing the ingress of dirt and moisture into the interior of the brake - which they do very efficiently. We have also added additional seals to the bearings in order to ensure they remain fully protected. And that's not all: ECO Disc brake callipers have cataphoretic dip-coating. All in all, these amount to the best prerequisites for a long brake life.

Providing optimum protection: innovative interior seals

BPW Disc Brake - Features and Benefits

- Quick and easy brake service through smart detailed solutions

- Effective heat dissipation by proven BPW flanged disc concept

- Low weight thanks to lightweight construction

- Optimally matched friction pairings (pads/brake disc)

- Special BPW disc alloy for high resistance to wear and cracking

- Reduced stock keeping because the same brake discs are used for 0 and 120 offset

- Symmetrical wear throughout the entire brake pad service life

- Increased disc surface area for optimum heat dissipation

- Sensitive response, good controllability and minimal thermal fading

WEAR and DAMAGE Characteristics on Friction Brakes

DISC Brake - click on image to download

Commercial Vehicles

Suspension Systems

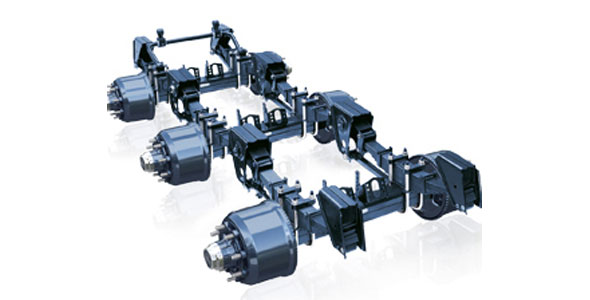

Setting the standards

Setting the standards in running gear technology

Setting the standards in running gear technology

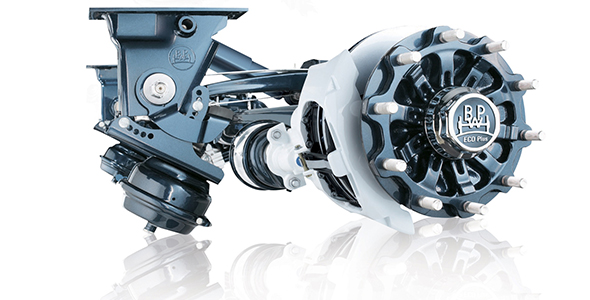

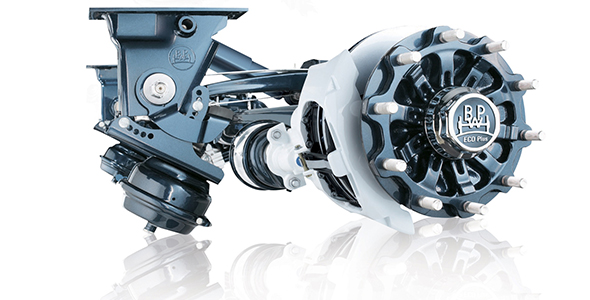

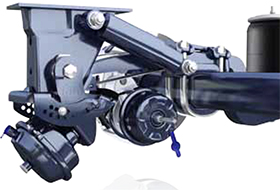

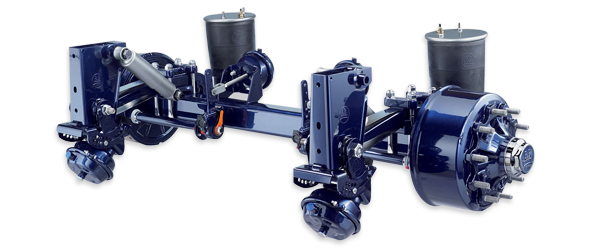

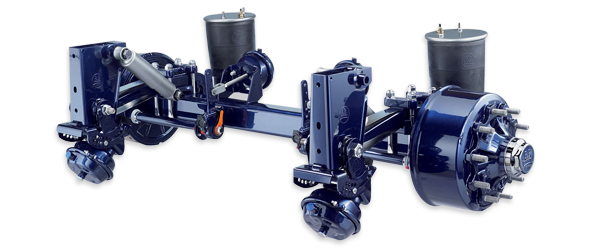

Short assembly times with modular design and the standard adjustable air suspension hanger bracket shows how well thought out and cost-effective the Airlight II is.

Fully installed with a clamped axle connection, it is maintenance-free in on-road applications. Furthermore, with the bolt-on Airlight II air suspension hanger bracket, BPW is offering more flexibility in production because it can be subsequently connected to the vehicle frame with the axle unit using cold-joining technology.

BPW Airlight II - Features and Benefits

- Low maintenance air suspension using weld on Axle connection for South African conditions

- For axle loads from 6 t to 10 t

- Weight optimisation for a bigger payload

- Easy installation and track setting of the axles using adjustable hanger brackets

- With 3-year ECO Plus warranty with unlimited mileage in on-road conditions

- Optionally with bolt-on air suspension hanger bracket

AIRLIGHT II Generic Spare Parts List - Download HERE >>

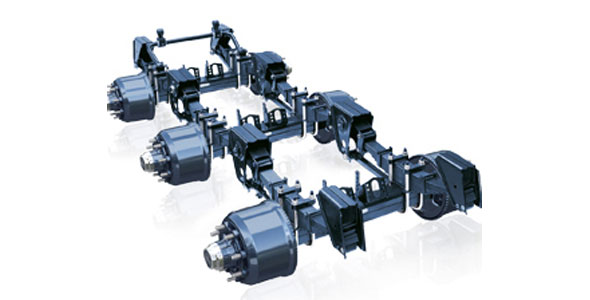

BPW Axle Lifts

To lift axles and reduce costs with BPW axle lift devices.

To lift axles and reduce costs with BPW axle lift devices.

Axle-lifting devices protect the tyres when the trailer is unladen or only bearing a light load; reduced rolling resistance will lead to fuel savings, amounting over long distances to extra money in your pocket. BPW air suspension axle can be fitted with axle lift device. At tandem axle suspensions one axle can be lifted, at tri-axle suspension maximal two axles can be lifted.

BPW Axle Lifts - Features and Benefits

- Reduced tyre wear

- Low inherent weight

- Moving-off aid for increased traction on the driven axle

- Compatible with Auto-Drop system (automatic lifting and lowering)

- Double-sided axle lift:

- Robust design with proven brake cylinders

- Installation without welding work (also for retrofitting) - Metal surfaces with cataphoretic dip-coating and zinc-phosphating KTLzn

Indestructible support on all routes

Indestructible support on all routes

Indestructible support on all routes

Whether on or off-road, local or long-distance - you can rely 100% on mechanical suspension systems from BPW. They're extremely robust and can master even the most exacting challenges.

Their simple design means they are also easy to repair when the infrastructure is poor. At the same time, axle loads of 9t and more pose no problems for our VB units.

BPW VB Suspension - Features and Benefits

- For axle loads from 9 t to 12 t (M/ME series) and from 14 t to 20 t (HD/HDE series)

- Can be used with one to three axles

- Available with parabolic springs (up to 12 t) or multi-leaf springs (up to 20 t)

- Static axle load equalisation using equalising beams

- Equalising beams mounted in maintenancefree rubber-steel bushes (9 t to 14 t) or in high-quality, long-life bronze bushes (9 t to 20 t)

- Torque arm mounted in maintenance-free rubber/steel bushes

- Stabilisers for vehicles available with a high centre of gravity height

- Easy track adjustment through one fixed and one adjustable connecting rod per axle

- Connecting rod located maintenance-free in rubber-steel-bushes

- Stabilizers can be supplied for vehicles with high centre of gravity heights

- Triaxle unit can be combined with a BPW LL self-steering axle (up to 14 t axle load)

- Supports with good weldability

- Front support brackets available with drawbar connection

- HD/HDE versions also offer thick-walled spring slides made of hardened and tempered steel alloy

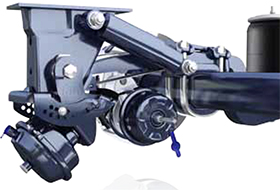

No compromising with comfort

No compromising with comfort for under 6 tons and over 10 tons

No compromising with comfort for under 6 tons and over 10 tons

For axle loads below 6t, above 10t or for special applications such as long-travel configurations for mega-trailers and off-road work.

With SL air suspension, you're banking on proven BPW technology - and on an air suspensions system which offers long service life and safety. And if your trailer should ever find itself in the workshop, you can be sure that it will be a short visit thanks to the high level of availability of spare parts.

BPW SL Air Suspension - Features and Benefits

- For axle loads from 4 t to 14 t

- Possible ride heights from 220 to 600 mm

- 100 mm wide trailing arms

- 1 and 2 leaf trailing arms available

- Robust and easy to service

- Suitable for long-stroke air bags

BPW Axle Lifts

To lift axles and reduce costs with BPW axle lift devices. Axle-lifting devices protect the tyres when the trailer is unladen or only bearing a light load; reduced rolling resistance will lead to fuel savings, amounting over long distances to extra money in your pocket. BPW air suspension axle can be fitted with axle lift device. At tandem axle suspensions one axle can be lifted, at tri-axle suspension maximal two axles can be lifted.

To lift axles and reduce costs with BPW axle lift devices. Axle-lifting devices protect the tyres when the trailer is unladen or only bearing a light load; reduced rolling resistance will lead to fuel savings, amounting over long distances to extra money in your pocket. BPW air suspension axle can be fitted with axle lift device. At tandem axle suspensions one axle can be lifted, at tri-axle suspension maximal two axles can be lifted.

BPW Axle Lift - Features and Benefits

- Reduced tyre wear

- Low inherent weight

- Moving-off aid for increased traction on the driven axle

- Compatible with Auto-Drop system (automatic lifting and lowering)

- Double-sided axle lift:

- Robust design with proven brake cylinders

- Installation without welding work (also for retrofitting) - Metal surfaces with cataphoretic dip-coating and zinc-phosphating KTLzn

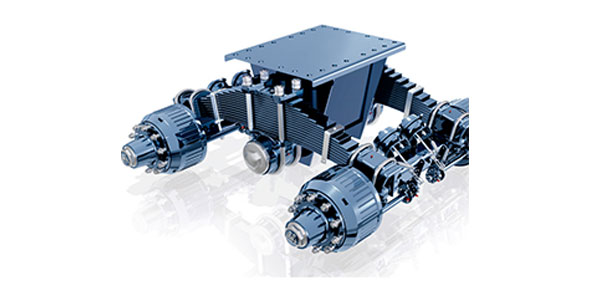

Reliable even in the toughest

Reliable even in the toughest working climate

Reliable even in the toughest working climate

The robust and long-lasting multiple leaf spring suspension systems in BPW units master even the harshest conditions. The suspension loads from 20,000 kg to 40,000 kg.

On roads, tracks or construction sites, in the icy Arctic or the tropical jungle, W suspension units have been designed for tandem axles and provide for reliable goods transport even under the most difficult conditions.

BPW W Bogie Suspension - Features and Benefits

- For axle loads from 2 x 10 t to 2 x 20 t

- Delivery as ready-to-mount, completely assembled unit

- Proven for many years in harsh off-road and tipper applications

- Construction with a high level of lateral stability

- Not sensitive to semitrailer tilt

- Very large axle load equalization paths

- Insensitive to brake caliper tilt

- Insensitive to warmth, cold and soiling

- High-quality mounting of the trunnion axle

- Optionally with one high support or two low supports

- Simple installation on the vehicle frame using bolted connection

BPW has always relied on the quality of its products to operate under the harshest of conditions.

Commercial Vehicles

Axles

Even heavy loads can be handled with ease

Even heavy loads can be handled with ease

BPW rigid axles are the strong backbone for your trailer. They are rugged, have an extremely high load capacity and are competitively light.

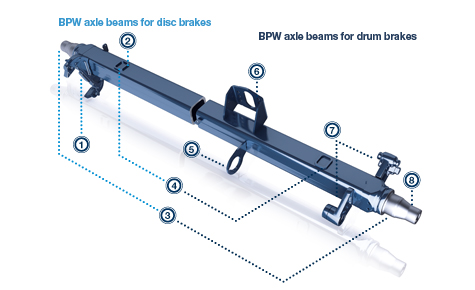

Function:

The axle stub of the axle beam holds the wheel bearings and therefore the hub to which the wheel is mounted by means of the wheel studs. Depending on the brake type, the brake disc or brake drum is connected to the hub. The brake anchor plate is welded onto the axle beam and provides the connection to the brake. The brake caliper is bolted on disc brake axles. On axles with drum brakes, it holds the brake shoes. The axle connection joints the axle to the suspension. The wheels, axle and suspension form the running gear and are mounted on the chassis of the trailer or the semitrailer.

The most important feature of a rigid axle is the connection between both ends of the axle through a single-part axle beam. If the position or angle of one wheel changes, e.g. spring compression on one side, the other wheels will be forced upwards. This also applies to changes in the camber and toe-in.

The axle transfers the static, dynamic and vertical wheel loads acting on the wheels, longitudinal forces acting in the direction of travel (e.g. caused by braking) as well as transverse forces which occur during cornering, for example:

(1) Brake anchor plate for disc brake, (2) Centring frame, (3) Track, (4) Spring centre, (5) Support bearing box, (6) Base plate, (7) Brake anchor plate for drum brake, (8) Axle stub

BPW Rigid Axles - Features and Benefits

- For axle loads up to 20 t

- Versions with air or mechanical suspension

- Versions with disc or drum brake

- With (mounted) BPW brake cylinders

- Wheels with or without offset

- Single or twin tyres

- Wheel sizes from 12 to 24 inches

- Stud or hub centring

- For disc wheels (steel or aluminium) or star wheels (TRILEX)

- ABS can be retrofitted

- All axles also have cataphoretic dip-coating and zinc-phosphating (KTLZn) at inaccessible points such as in cavities to provide optimum protection against corrosion

- BPW axles and suspension units are resistant to temperature effects in line with NATO requirements.

* The specified axle loads (see "Technical details") are maximum values on the ground up to 105 km/h (65 mph). In vehicles with a slower permitted maximum speed, the following axle load increases are possible with BPW: Vmax. 40 km/h + 10%, Vmax. 25 km/h + 25%, Vmax. 10 km/h + 40%. Please also refer to the load rating data provided by the wheel and tyre manufacturers.

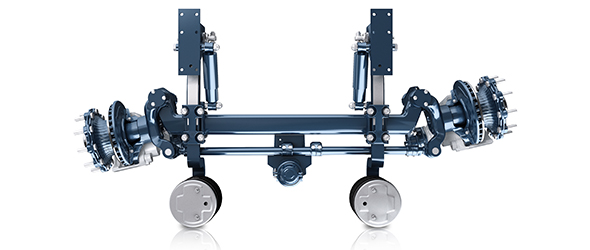

Better through the bends

Better through the bends

Better through the bends

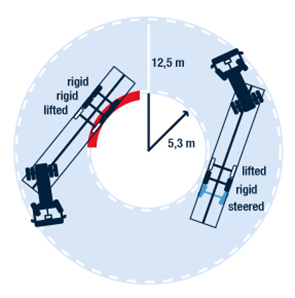

The LL self-steering axle is the economic miracle of all the BPW axles. It shows off its strengths particularly when tight manoeuvring is required in delivery and distribution haulage.

Thanks to its greater manoeuvrability on corners and when making turns, you benefit from more straightforward vehicle handling, less tyre wear and lower fuel consumption. Over a mileage of 100,000 kilometres that adds up to the impressive amount of approx. 1,000 litres of fuel and more than 4 tyres per vehicle. Just work that out for your entire fleet!

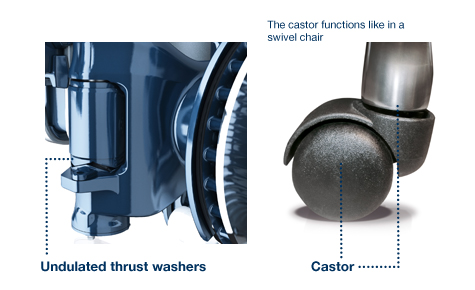

Function of the self-steering axles:

LL stands for "load-dependant steering stabilisation" and it describes the unique functional principle of the BPW self-steering axle. Conventional steering axle designs require steering stabilisers powered from an external source - this is not the case with the BPW self-steering axle. The axle beam and axle stub are connected to undulating thrust washers via steering pivots. When driving straight ahead (zero position), the undulations in the thrust washers keep the wheels on track. The weight of the vehicle presses the undulating contours of the upper and lower thrust washers together. The wheels remain stable in the correct forwards position. When the semitrailer follows the tractor unit through a bend, the wheel castor ensures the wheels turn in accordance with the curve radius (the thrust washers slide over one another).

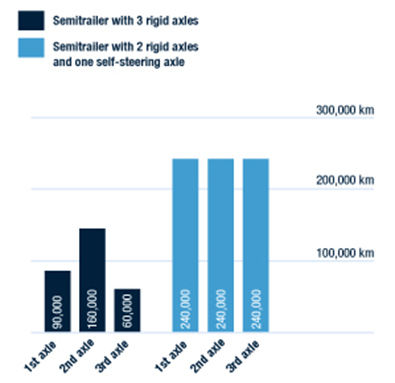

The frictional resistance changes according to the load on the axle. As a result, a steering angle (of 8° to 27°, depending on the vehicle type) is established according to the load, and solely by mechanical control. The drag link connecting the wheels uses a steering lock to prevent the wheels from steering when the vehicle reverses. The steering axle means that the unit corners better and follows the same track as the tractor unit almost identically. The lateral tyre forces arising are optimally distributed between all the axles, for example in a 3-axle vehicle. As every axle experiences significantly lower lateral tyre forces, the mileage of the front axle increases by up to 50% - whereas the rear axle mileage increases by up to 70%.

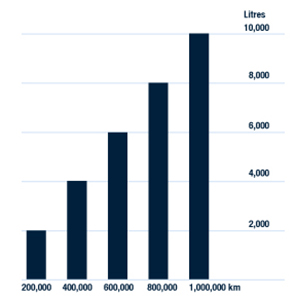

Tyre Mileage (km) in distribution haulage

Fuel Saving from BPW self-steering axle in proportion to mileage - here taking the example for distribution haulage

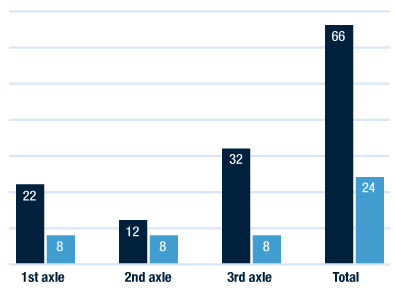

Tyre Consumption on a three-axle vehicle over 100 000 km, used in distribution haulage

The BPW self-steering axle guarantees compliance with the turning-circle regulations, even when the first axle is lifted

BPW LL Self-Steering Axles - Features and Benefits

- For axle loads from 6.4 t to 14 t

- Versions with disc or drum brake

- Lightest self-steering axle

- Steering stabilisation solely load-dependent

- Significantly lower and more even tyre wear: save more than 4 tyres over 100,000 kilometres

- Significantly lower fuel consumption: up to 1,000 litres over 100,000 kilometres

- Greater manoeuvrability, reduced transport space requirement, fewer expensive incidents of tyre damage

- Less strain on the body, frame and road

- Exact tracking when changing lanes

- Particularly recommendable with the 44 tonnes regulation*

- Simplified installation thanks to optional 3-D trailing arms, no retracted frame required

- Permitted ratio of rigid axles to steering axles 1:1 (also applies with a lifted first axle of a tri-axle suspension)

- Higher resale value

- Cataphoretic dip-coating with zinc-phosphating

Commercial Vehicles

Accessories

Setting the standards

Always be up top date

Always be up top date

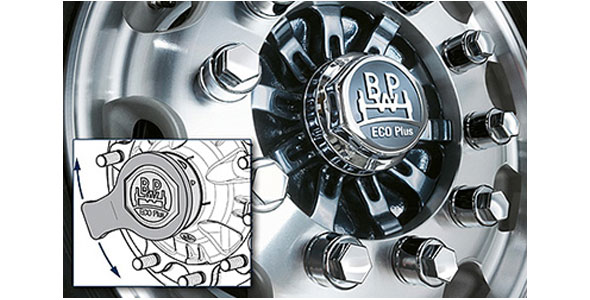

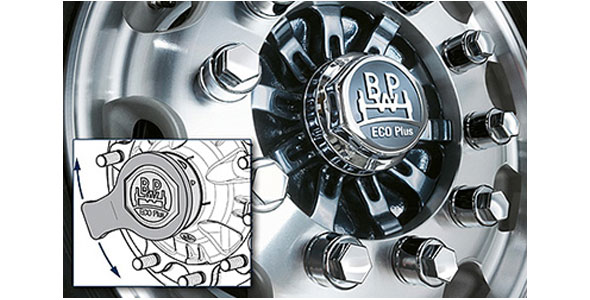

The BPW ECO Meter is a kilometre counter integrated in the hub cap. It makes sure that you can always check the actual mileage of your trailers, even when they are used with different tractor vehicles.

The ECO Meter has been further optimised for the ECO Plus 2 axle generation: for example, it has been given a designed hub cap, and the visible contacts have been moved inside the housing for optimum protection against dirt.

BPW ECO Meter for ECO Plus 2 - Features and Benefits

- Sensor contacts and display unit are completely protected behind a plastic window

- The performance, the extent of roll motion and the battery status are all displayed

- The electronics printed circuit board is cast in plastic in the water-tight and indestructible hub cap

- Adjustment of the wheel circumference is effected via the display unit (default setting 385/65 R22.5)

- Licensed under the Regulation on Transporting Hazardous Goods by Road

- Just one sort for all tyre sizes

- More precise than a mechanical ECO Meter

- Can also easily be read in the dark

- Cannot be tampered with

- Check on tyre performance

- Easy assembly through change of hub cap

- Cataphoretic dip-coating with zinc-phosphating

The right tool for saving time

The right tool for saving time

The right tool for saving time

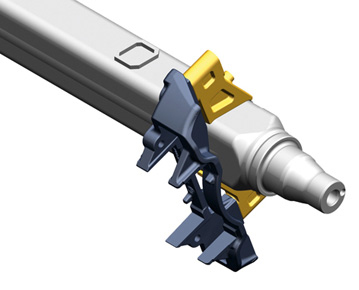

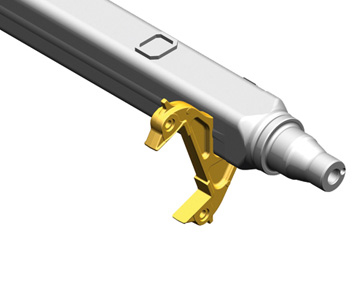

There is a long tradition of special tools and measuring instruments at BPW, based on decades of experience. They facilitate service work on BPW units, save working time and thereby increase your efficiency.

The tool assortment has also been adapted to the new ECO Plus 2 axle generation and supplemented accordingly.

BPW trailer axles with the ECO Plus 2 unit have hub caps (and ECO Meters) with a bayonet fitting. The bayonet lock replaces the former threaded connection. A 120 mm installation spanner (BPW part number 03.339.05.02.0) is needed for fitting or removing the new hub caps with the bayonet fitting.

An impact driver must not be used for fitting / removing hub caps or ECO Meters with a bayonet fitting!

BPW accessories and tools are designed for the modules or components of the product range and are divided into tools for:

- Axle beam and wheel bearings

- Drum brakes

- Disc brakes

- Suspension systems

In addition, BPW offers special measuring instruments for checking dimensions (e.g. for toe-in) on axles and units.

Please refer to the latest BPW workshop manuals for details on how to use the tools correctly.

BPW Tools and Measuring Instruments - Features and Benefits

- Practically tested configuration

- Use of high-quality materials. Permanent quality assurance guarantees a consistent quality level

- Long-life and resistant to wear

- Simple handling

- Favourable price/performance ratio: Often, buying high-quality tools is less expensive in the long run. particularly if the tools are needed regularly and the easy use must be ensured on each occasion.

ECO Disc Tool Case Tools for BPW Axles

- click on to download - click on to download

A useful accessory for trailers

A useful accessory for trailers

A useful accessory for trailers

The BPW Load Indicator is a useful accessory for trailers on Air suspension that can give reliable information on the load on the axle or axle group.

The load on the trailer is directly proportional to the pressure in the Air bags, and connecting an air pressure gauge, calibrated to read the load on the axle group, results in an inexpensive way to know you are not over (or under!) loaded.

BPW Axle Load Pressure Gauge - Features and Benefits

- Reliable display of the loading condition

- Increased protection with silicone oil damping of the gauge

- No need to weight the trailer specifically when loading and unloading

- Available for air bag sizes 300 mm and 360 mm

- Also available as a complete kit including pressure gauge, bolted connection, shut-off tap and installation diagram